How to Start an FRP Rebar Manufacturing Plant

A Practical Guide to Equipment Selection, Plant Setup, and Production Planning

With the increasing demand for corrosion-resistant and lightweight reinforcement materials, FRP rebar has become a strategic alternative to traditional steel rebar in infrastructure, marine, and transportation projects. As a result, many investors and manufacturers are exploring how to start an FRP rebar manufacturing plant to enter this growing market.

Unlike conventional steel rebar factories, FRP rebar plants rely on composite pultrusion technology, which requires precise process control and specialized equipment. Proper planning at the early stage plays a critical role in long-term production stability and return on investment.

Step 1: Market Analysis and Product Positioning

Before setting up an FRP rebar manufacturing plant, it is essential to conduct a detailed market analysis. This includes understanding local construction standards, infrastructure investment trends, and the acceptance level of FRP rebar in your target market.

Key questions to consider include:

- Which rebar diameters are most commonly used?

- Are local projects focused on bridges, marine structures, or buildings?

- Which standards must the products comply with?

Clear product positioning helps define equipment specifications and production capacity, avoiding unnecessary investment during the initial stage.

Step 2: Choosing the Right FRP Rebar Manufacturing Technology

The most widely adopted technology for FRP rebar production is pultrusion. This continuous process ensures consistent fiber alignment, stable resin impregnation, and uniform curing, which are essential for mechanical performance.

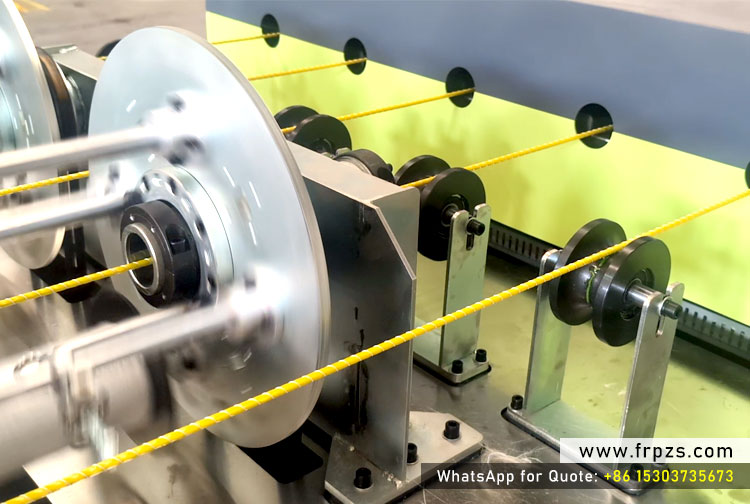

A professional FRP rebar production line typically integrates fiber creels, resin impregnation units, heated molds, pulling systems, and automatic cutting devices. Compared with batch processes, pultrusion-based systems offer higher efficiency and better product consistency.

Selecting a reliable FRP rebar machine is the foundation of plant success. Equipment stability directly affects output quality, downtime frequency, and long-term operating costs.

FRP Rebar Manufacturing Equipment

Step 3: Plant Layout and Infrastructure Planning

Proper plant layout improves production efficiency and safety. An FRP rebar manufacturing plant should be divided into functional zones, including raw material storage, pultrusion production area, curing and cooling zone, cutting and finishing area, and finished product storage.

Key infrastructure considerations include:

- Stable power supply for heating and pulling systems

- Ventilation and environmental control for resin handling

- Sufficient space for mold replacement and maintenance

- Safe storage for resins and fibers

A well-planned layout reduces material handling time and supports future capacity expansion.

Step 4: Equipment Configuration and Capacity Planning

Production capacity planning should align with market demand and investment budget. Typical FRP rebar manufacturing lines support diameters ranging from 6 mm to 32 mm, with production speeds depending on product size and curing requirements.

- Production speed: 0.5 – 2.5 m/min

- Daily output: 2 – 8 tons per line

- Labor requirement: 2–3 operators per shift

One major advantage of pultrusion equipment is flexibility. By changing molds and adjusting parameters, a single line can produce multiple rebar diameters, allowing manufacturers to respond quickly to market demand.

Step 5: Raw Materials and Process Control

FRP rebar performance depends heavily on raw material selection and process stability. Glass fiber type, resin formulation, and curing temperature must be carefully controlled to achieve consistent mechanical properties.

Key process control factors include:

- Fiber tension and alignment

- Resin viscosity and impregnation time

- Mold temperature distribution

- Pulling speed synchronization

Advanced FRP rebar machines allow precise adjustment of these parameters, reducing defect rates and improving yield.

Step 6: Quality Control and Testing

Quality control is essential for gaining acceptance in engineering projects. FRP rebar manufacturing plants should implement routine inspection and testing procedures to ensure consistent product performance.

Common quality indicators include tensile strength, modulus, surface bonding performance, and dimensional accuracy. Stable equipment and standardized operating procedures simplify quality management.

Step 7: Training, Commissioning, and Technical Support

Even with advanced equipment, proper training is critical. Operators must understand pultrusion principles, parameter adjustment, and routine maintenance.

Working with an experienced equipment manufacturer ensures smooth installation, commissioning, and operator training. Many production issues can be avoided when technical support is available during the early production stage.

Professional FRP Rebar Machine Supplier

Investment Cost and Return Considerations

The initial investment for an FRP rebar manufacturing plant depends on equipment configuration, automation level, and plant scale. Compared with steel rebar production, FRP rebar manufacturing requires lower energy consumption and fewer workers.

Key factors affecting return on investment include production efficiency, market pricing, raw material sourcing, and equipment uptime. Selecting reliable machinery reduces long-term operational risk and improves profitability.

Final Thoughts

Starting an FRP rebar manufacturing plant requires careful planning, reliable equipment, and professional technical support. From market analysis to production line selection, each decision directly affects long-term success.

By choosing a stable pultrusion-based FRP rebar production line and working with an experienced equipment supplier, manufacturers can enter the market faster, reduce risks, and build a competitive FRP rebar business.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data