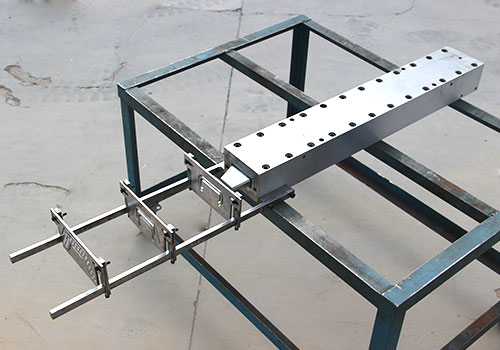

In the world of composite manufacturing, the quality of the final FRP (Fiberglass Reinforced Polymer) profile is determined long before the raw materials enter the machine. The secret lies in the pultrusion die. As a critical component of the production line, the mold defines the dimensional accuracy, surface finish, and structural integrity of the composite shapes.

At Henan Zhongsheng Composite Materials Co., Ltd, we specialize in designing and engineering high-precision pultrusion tooling that empowers manufacturers to produce world-class fiberglass products for global infrastructure and industrial markets.

Why Does Pultrusion Die Design Matter?

The pultrusion process involves pulling continuous fibers through a resin bath and then through a heated steel die. Inside this die, the material undergoes polymerization. If the die is not engineered with extreme precision by a professional manufacturer like Henan Zhongsheng, several issues can occur:

- Internal Cracking: Improper heat distribution within the mold can cause thermal stress.

- Surface Defects: Low-quality steel or poor polishing leads to friction and surface tearing.

- Dimensional Instability: Incorrect shrinkage allowance results in profiles that don't meet engineering tolerances.

Technical Excellence: Our Mold Manufacturing Standards

To ensure our clients achieve the highest ROI, our pultrusion dies are manufactured using a rigorous technical approach:

| Feature | Technical Specification | Client Benefit |

|---|---|---|

| Material | High-grade P20 / Cr12Mov / H13 Steel | Longer service life and wear resistance. |

| Surface Treatment | Hard Chrome Plating & Mirror Polishing | Reduces pulling force and improves gloss. |

| Hardness | HRC 58-62 after heat treatment | Resists abrasion from glass and carbon fibers. |

| Tolerance | Up to ±0.02mm | Perfect fit for complex structural assemblies. |

Custom Solutions for Complex Geometries

Modern engineering often requires more than just simple rods or tubes. From multi-cavity designs to ultra-thick structural I-beams, the engineering team at Henan Zhongsheng Composite Materials utilizes advanced CAD/CAM software to simulate the curing process. This ensures uniform curing even for the most complex profiles.

"A superior mold is not just a piece of steel; it's a thermal management system that dictates the speed and quality of your entire production line."

Integration with Pultrusion Equipment

For a seamless production experience, our dies are perfectly calibrated to work with our advanced Pultrusion Machines. Whether you are producing fiberglass rebar or large-span profiles, the synergy between the machine's pulling power and the die's geometry is vital for operational efficiency.

Contact Us for Expert Solutions

Ready to develop a new FRP product or optimize your production line? Henan Zhongsheng Composite Materials Co., Ltd provides professional technical support and custom mold designs tailored to your needs.

Email: Jessica@frpzs.com

WhatsApp: +86 15303735673 (Click to Chat)

Website: www.frpzs.com

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data