WPC vs FRP

In today's construction and industrial landscape, the demand for durable, low-maintenance, and weather-resistant materials is higher than ever. Two composite materials often considered for demanding environments are Wood Polymer Composite (WPC) and Fiberglass Reinforced Plastic (FRP). Both are engineered to outperform traditional wood or metal in corrosive or extreme climate conditions, but which is more suitable for truly harsh environments?

Understanding the Materials

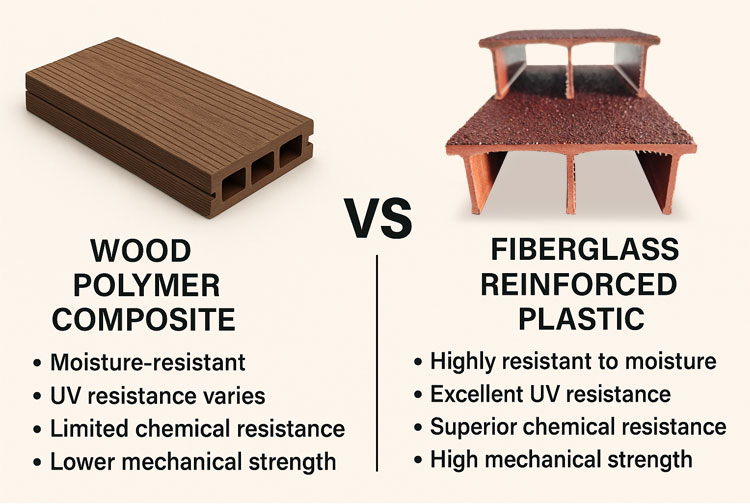

WPC (Wood Polymer Composite) is made from a combination of wood fibers and thermoplastics such as polyethylene, polypropylene, or PVC. It’s widely used in decking, fencing, and outdoor furniture. WPC offers the aesthetic appeal of wood with reduced maintenance needs.

FRP (Fiberglass Reinforced Plastic) is a composite material made from thermosetting resin reinforced with glass fibers. It is manufactured through methods like pultrusion or hand lay-up and is renowned for its strength, chemical resistance, and longevity. FRP is widely used in structural profiles, ladders, grating, cable support systems, and industrial platforms.

Performance Comparison in Harsh Environments

1. Moisture and Weather Resistance

WPC is moisture-resistant but not entirely waterproof. In humid or rainy environments, especially with fluctuating temperatures, WPC can absorb moisture over time, leading to warping or microbial growth. FRP, on the other hand, is completely non-porous and inert to water exposure. It does not swell, rot, or promote mold growth, making it ideal for marine or coastal applications.

2. UV Resistance and Color Retention

WPC tends to fade and degrade under prolonged UV exposure unless specially treated. FRP profiles manufactured using UV-stabilized resins can maintain their color and mechanical strength for decades, even in desert or high-altitude environments.

3. Temperature and Fire Resistance

WPC has a lower heat deflection temperature and may deform under high thermal stress. It also has limited fire resistance unless additives are used. In contrast, FRP can be formulated with fire-retardant resins and withstand extreme temperatures, especially in industrial or oil and gas facilities.

4. Chemical and Corrosion Resistance

FRP offers excellent chemical resistance and is often used in chemical plants, wastewater treatment facilities, and corrosive industrial environments. WPC is not designed for chemical exposure and deteriorates when subjected to acids, bases, or solvents.

5. Mechanical Strength and Load Bearing

FRP profiles such as beams, rods, and channels have high tensile and flexural strength, comparable to or exceeding steel on a strength-to-weight basis. WPC, while suitable for light-duty applications, cannot match the structural performance of FRP.

Environmental and Lifecycle Considerations

Both WPC and FRP are considered eco-friendly compared to traditional materials. WPC uses recycled wood and plastics, and FRP can last over 50 years with minimal maintenance, reducing lifecycle costs and resource use. However, FRP’s longer service life in harsh environments translates into fewer replacements and reduced waste over time.

Application Examples

- WPC: Residential decking, garden fences, park benches

- FRP: Cable trays, marine docks, industrial platforms, cooling tower components, and offshore structures

Conclusion – Which One Wins?

If your application is in a relatively mild, decorative, or light-load environment, WPC may offer a cost-effective and visually pleasing solution. However, when operating conditions involve chemicals, high humidity, salt spray, high temperatures, or demanding mechanical loads, Fiberglass Reinforced Plastic (FRP) is the superior material.

At www.frpzs.com, we specialize in the design and manufacturing of FRP pultrusion profiles and molds tailored for the toughest conditions. Our fiberglass solutions are widely used across the globe in infrastructure, transportation, and energy industries, proving time and again their value in demanding environments.

Contact us to learn more about how FRP can enhance your projects and reduce maintenance costs over time.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data