Introduction:

In the construction and manufacturing industries, fiberglass grating has become an indispensable material due to its exceptional properties. Fiberglass grating is a lightweight, strong, and durable material that is resistant to corrosion, chemicals, and UV rays. These characteristics make it an ideal choice for a wide range of applications, including flooring, platforms, walkways, stairs, safety barriers, and rooftops.

Types of Fiberglass Grating:

Fiberglass grating is broadly categorized into two main types: pultruded fiberglass grating and molded fiberglass grating. Each type has its unique properties and applications.

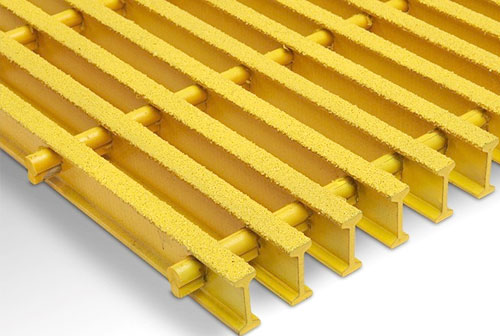

Pultruded Fiberglass Grating:

Pultruded fiberglass grating is manufactured by pulling continuous fiberglass roving through a heated die. The die shapes the roving into the desired grating pattern, and the resin is cured to harden the grating. This process results in a strong and lightweight grating with a consistent bar size and spacing.

Molded Fiberglass Grating:

Molded fiberglass grating is produced by pouring liquid resin into a mold that is shaped with the desired grating pattern. The resin is then cured to solidify the grating. This method allows for the creation of more complex shapes and sizes compared to pultruded grating.

Specialty Fiberglass Grating:

In addition to pultruded and molded fiberglass grating, there are also several specialty gratings designed for specific applications:

Fire-retardant fiberglass grating: This type of grating is designed to resist fire and is suitable for use in areas where fire safety is a critical concern.

Fireretardant Fiberglass Grating

Conductive fiberglass grating: This type of grating is designed to conduct electricity and is used in applications where static electricity poses a hazard.

Micro fiberglass grating: This type of grating has very small openings, making it ideal for use in applications where small objects need to be prevented from falling through the grating.

Applications of Fiberglass Grating:

Fiberglass grating's versatility extends to its wide range of applications across various industries:

Industrial: Fiberglass grating is commonly used in industrial settings, such as factories, power plants, and oil refineries, due to its resistance to corrosion, chemicals, and UV rays.

Commercial: Fiberglass grating is also prevalent in commercial settings, including office buildings, retail stores, and restaurants, as it is slip-resistant and easy to clean, ensuring safety and hygiene.

Municipal: Fiberglass grating finds applications in municipal projects, such as bridges, sidewalks, and walkways, due to its strength and durability, which can withstand heavy foot traffic.

Marine: Fiberglass grating is often used in marine applications, such as boats, docks, and piers, as it is resistant to corrosion and UV rays, making it suitable for saltwater environments.

Conclusion:

Fiberglass grating has emerged as a superior material choice for various applications due to its exceptional strength, durability, corrosion resistance, and versatility. With its diverse types, including pultruded, molded, and specialty gratings, fiberglass grating caters to a wide range of industry needs. Whether it's ensuring safety in industrial settings, enhancing aesthetics in commercial spaces, or providing durability in municipal projects, fiberglass grating proves to be a reliable and long-lasting solution.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data