The Growing Demand for Customized FRP C Channel Sizes in Infrastructure Projects

As infrastructure projects worldwide continue to pursue longer service life, improved corrosion resistance, and reduced maintenance costs, Fiber Reinforced Polymer (FRP) profiles have become a preferred alternative to steel and aluminum. Among them, FRP C channels are widely used in bridge systems, industrial platforms, municipal construction, and coastal engineering. In recent years, the demand for customized FRP C channel sizes has increased significantly, driven by engineering needs that go far beyond the limitations of standard metal profiles.

Why Custom FRP C Channel Sizes Are Becoming Essential

Modern construction projects often involve specific load requirements, unique installation conditions, and exposure to harsh environments. Engineers and contractors are therefore seeking FRP C channels that can be customized in dimensions, thickness, resin formulation, and fiber reinforcement structure. Custom sizing allows the profile to meet exact structural requirements while maintaining lightweight advantages and long-term durability.

Key Advantages Driving the Growth

1. Excellent Corrosion Resistance

Unlike steel, FRP C channels do not rust or erode when exposed to moisture, saltwater, or chemical environments. Customized sizes ensure optimal performance in sectors such as wastewater treatment plants, coastal boardwalks, and industrial facilities with corrosive atmospheres.

2. High Strength-to-Weight Ratio

FRP materials offer strong mechanical properties while remaining much lighter than metal options. Custom dimensions allow for efficient structural design, reducing installation time and minimizing transportation costs.

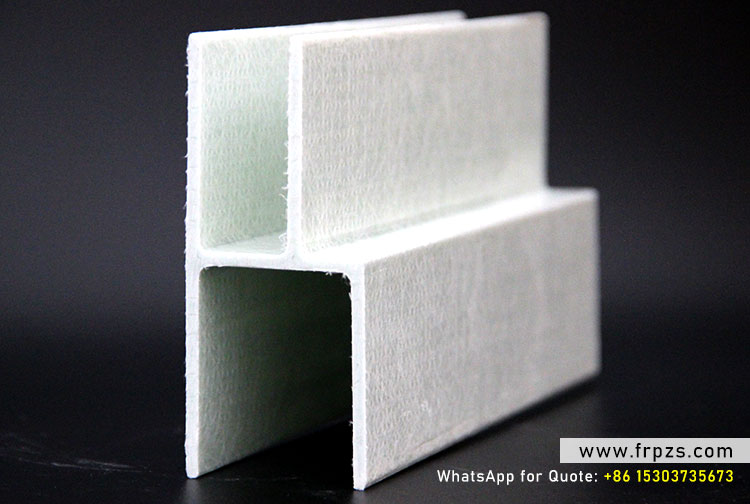

White Fiberglass (FRP) special shape U-channel profile, ideal as a corrosion-resistant cable tray or structural support base. Custom pultruded profile.

3. Longer Service Life With Minimal Maintenance

Infrastructure owners increasingly prefer materials with low lifecycle costs. FRP C channels can reach a service life of 30–50 years with almost no maintenance. Custom-manufactured channels ensure that each project receives a profile engineered for long-term stability.

4. Flexibility for Complex Engineering Requirements

Pultrusion technology provides high dimensional accuracy, making it possible to manufacture FRP C channels that match specific design tolerances, connection needs, and load-bearing expectations. This level of customization is crucial for modern infrastructure applications.

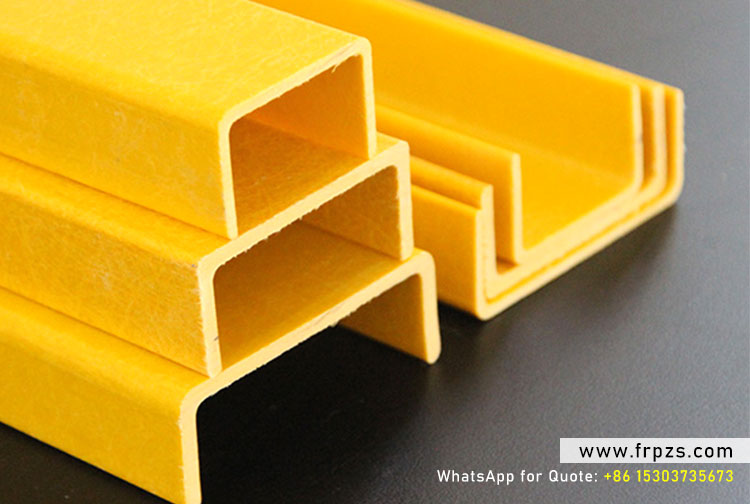

Yellow Fiberglass (FRP) Handrail Fitting Profiles - Custom GRP Profiles by FRPZS

Typical Applications in Infrastructure Projects

- Pedestrian bridges and composite walkways

- Electrical and telecom support systems

- Metro and railway cable management systems

- Oil, gas, and chemical platforms

- Cooling tower support structures

- Coastal and marine engineering projects

Each of these applications often requires unique structural dimensions and environmental resistance, reinforcing the rapid rise in customized FRP C channel demand.

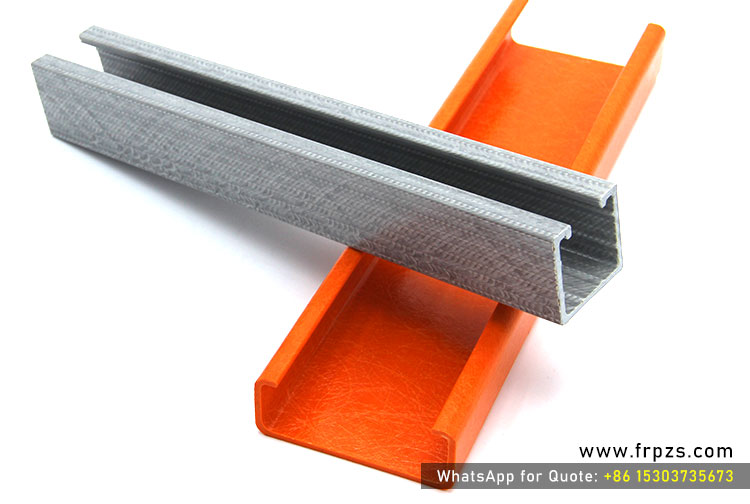

Close-up of a white Fiberglass (FRP) I-beam or H-beam structural profile, showcasing its pultruded texture. Ideal for corrosion-resistant construction projects.

How Manufacturers Support This Trend

Advanced FRP manufacturers now provide full customization options, including profile geometry, wall thickness, resin system (vinyl ester, polyester, epoxy), fiber orientation, surface finish, and UV resistance. These capabilities ensure that FRP C channels can be produced according to international standards and tailored to each engineering scenario.

Conclusion

The shift toward customized FRP C channel sizes is reshaping the global infrastructure market. With superior durability, corrosion resistance, and adaptability, FRP profiles are becoming the preferred choice for large-scale and long-term construction. As the demand for sustainable and resilient materials continues to rise, customized FRP C channels will play an increasingly important role in future engineering development.

Close-up of two yellow FRP custom grooved and specialized structural profiles, ideal for industrial flooring or decking applications.

If you need customized FRP C channel sizes or other FRP structural profiles, feel free to contact us at any time.

Website: www.frpzs.com

Email: Jessica@frpzs.com

WhatsApp: +86 15303735673

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data