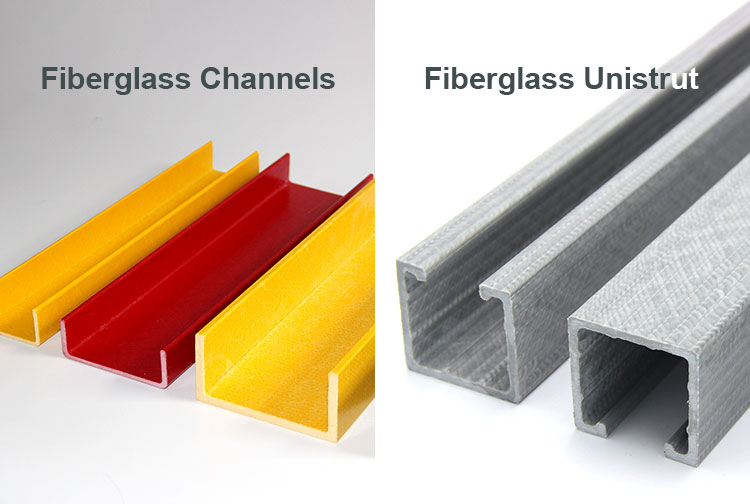

Fiberglass structural profiles are increasingly specified in projects that require a high strength-to-weight ratio, long-term corrosion resistance, and electrical insulation. Two of the most requested products are Fiberglass Channels (FRP Channels) and Fiberglass Unistrut (FRP Strut). Although both are pultruded FRP profiles, they are engineered for different types of assemblies and installation methods. This article explains how they differ and how to choose the right option for your project.

1) Profile Design

- Fiberglass Channels: Open C or U-shaped section with flat webs and flanges. The geometry prioritizes bending capacity and straightforward framing.

- Fiberglass Unistrut: C-shaped section with inward-turned lips and a continuous inner slot. The lips accept sliding nuts and modular fittings for quick assembly.

2) Connection & Installation Method

- Channels: Typically drilled and fastened with bolts, angles, and clamps. Ideal for fixed frames, beams, and long-span members where connections are predetermined.

- Unistrut: Uses sliding spring nuts, brackets, and standardized hardware. Components can be positioned and re-positioned without drilling, which speeds up installation and future adjustments.

3) Typical Applications

- Channels: Equipment frames, platforms, walkways, guardrail rails and posts, secondary beams, perimeter members.

- Unistrut: Solar PV racking, cable tray supports, pipe hangers, instrumentation racks, HVAC and electrical mounting rails where modularity is essential.

4) Performance Considerations

- Strength & Stiffness: Both are strong relative to weight. Channels are often favored for primary framing; Unistrut excels in secondary supports and adjustable assemblies.

- Corrosion Resistance: Both provide excellent resistance to salt, moisture, and chemicals when specified with suitable resin (e.g., vinyl ester for harsh service).

- Electrical & Thermal Insulation: Both are non-conductive and thermally insulating—advantages over metallic systems in substations, coastal sites, and cold storage.

- UV & Weathering: UV-stabilized resins and surface veils are available for long-term outdoor exposure.

5) Side-by-Side Comparison

| Feature | Fiberglass Channels | Fiberglass Unistrut |

|---|---|---|

| Profile Geometry | Open C/U section | C section with in-turned lips & slot |

| Primary Connection | Drilled bolt joints, angles, clamps | Sliding nuts + modular brackets |

| Installation Speed | Medium | High (minimal drilling) |

| Adjustability | Medium (fixed hole locations) | Very high (tool-free repositioning) |

| Best Use | Primary frames, beams, platforms | Pipes, cables, PV mounts, MEP racks |

| Installed Cost | Lower material cost; more drilling | Slightly higher material; faster assembly |

6) Selection Guide

Choose Fiberglass Channels when your structure is primarily static, loads are known, and you want simple, robust framing with traditional bolted joints. Examples: equipment skids, mezzanine frames, platform beams.

Choose Fiberglass Unistrut when you need rapid installation, frequent layout changes, or ongoing expansion. Examples: solar PV mounting rails, multi-tier cable supports, pipe racks, instrument stands.

7) Life-Cycle Advantages

Both solutions offer low maintenance over decades in coastal, chemical, and high-humidity environments. Compared with metallic systems, FRP does not rust, minimizes grounding requirements, and reduces downtime. Projects often realize lower total cost of ownership through faster installation (Unistrut) or simplified primary framing (Channels), plus minimal repainting or replacement.

Conclusion

Fiberglass Channels and Fiberglass Unistrut are complementary FRP solutions. Channels excel in fixed, load-bearing frames, while Unistrut leads in modular, adjustable, and fast-install assemblies. By matching the profile to the installation method and service environment, you can optimize structural performance, safety, and total project cost.

Looking for engineering support or cut-to-length supply? Contact us: www.frpzs.com | Jessica@frpzs.com | WhatsApp: +86 15303735673

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data