Square Tube Applications and Advantages in Modern Composite Structures

Square tube profiles play a critical role in modern construction, infrastructure, and industrial manufacturing. As global projects demand lighter weight, higher durability, and longer service life, traditional steel square tubes are increasingly being complemented—or replaced—by FRP (Fiber Reinforced Plastic) square tube solutions. These advanced composite square tubes offer superior corrosion resistance, electrical insulation, and design flexibility, making them a strategic material choice across multiple industries.

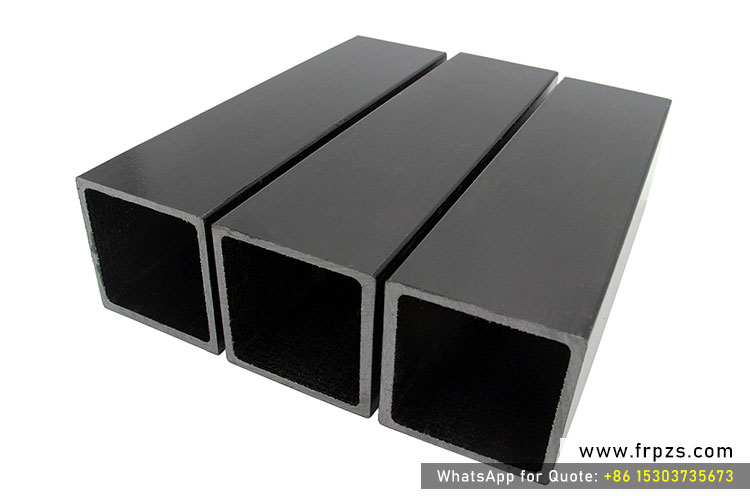

What Is a Square Tube in Structural Engineering?

A square tube is a hollow structural section (HSS) with equal-length sides, widely used for load-bearing frames, support columns, platforms, walkways, and modular systems. Compared with round or rectangular profiles, square tubes provide balanced strength distribution, excellent torsional resistance, and ease of connection in prefabricated assemblies.

In composite engineering, FRP square tubes are typically produced using pultrusion technology, ensuring consistent fiber alignment, precise dimensions, and stable mechanical performance.

Why FRP Square Tubes Are Gaining Market Attention

1. Corrosion Resistance in Harsh Environments

Unlike steel square tubes, FRP square tubes do not rust or corrode when exposed to moisture, salt spray, chemicals, or UV radiation. This makes them ideal for coastal infrastructure, chemical plants, wastewater treatment facilities, and marine structures.

2. High Strength-to-Weight Ratio

FRP square tubes deliver impressive structural strength while remaining significantly lighter than steel. Reduced weight lowers transportation costs, simplifies installation, and minimizes the need for heavy lifting equipment on-site.

3. Electrical and Thermal Insulation

As non-conductive materials, fiberglass square tubes are widely used in power substations, cable support systems, and electrical safety structures where insulation performance is critical.

4. Long Service Life and Low Maintenance

FRP square tubes maintain stable performance over decades with minimal maintenance. This life-cycle advantage is increasingly valued in infrastructure projects focused on long-term cost efficiency.

Common Applications of Square Tube Profiles

- Structural frames and support systems

- FRP handrails and guardrail posts

- Industrial platforms and walkways

- Solar mounting structures

- Cable trays and equipment supports

- Modular buildings and prefabricated systems

In many of these applications, composite square tubes outperform metal alternatives by offering consistent performance in aggressive operating environments.

Manufacturing Process of FRP Square Tubes

FRP square tubes are commonly manufactured using continuous pultrusion. Glass fibers are pulled through resin impregnation, precision molds, and controlled curing zones to form rigid square profiles with tight tolerances.

This process allows for:

- Custom wall thickness and dimensions

- Optimized fiber orientation for load requirements

- Consistent quality for large-volume production

Customization Options for Square Tube Profiles

Modern projects rarely rely on standard sizes alone. Composite square tubes can be customized to meet specific engineering and architectural needs, including:

- Different side dimensions and wall thicknesses

- Fire-retardant or UV-resistant resin systems

- Color integration without secondary coating

- Surface treatments for bonding or anti-slip performance

Square Tube vs Traditional Steel: A Strategic Comparison

While steel square tubes remain common, their limitations in corrosive or electrically sensitive environments are becoming increasingly apparent. FRP square tubes provide a future-oriented alternative, aligning with sustainability goals, reduced maintenance budgets, and evolving safety standards.

For engineers and procurement teams, material selection is no longer based solely on upfront cost, but on long-term performance, reliability, and total ownership value.

Conclusion: The Future of Square Tube Structures

As infrastructure and industrial projects continue to evolve, square tube profiles manufactured from advanced composite materials are becoming an essential component of modern structural systems. With their combination of strength, durability, and adaptability, FRP square tubes are well-positioned to support the next generation of construction and industrial innovation.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data