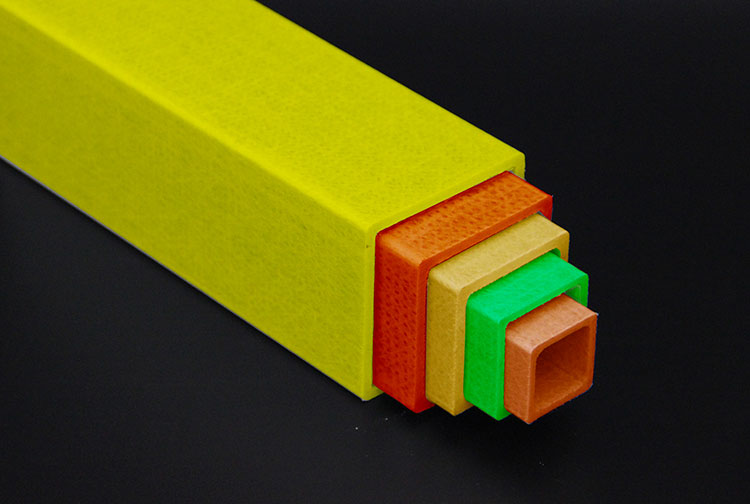

Image: Custom fiberglass square tubes used in a structural framework.

Introduction to Custom Fiberglass Square Tubes

Fiberglass square tubes have emerged as a game-changer in industries requiring strong, lightweight, and corrosion-resistant materials. Unlike traditional materials like steel or aluminum, custom fiberglass square tubes provide unparalleled flexibility in design and application. Whether you're working on a marine project, constructing a durable framework, or designing an innovative industrial structure, these tailored solutions meet specific needs with precision. This article dives deep into the world of custom fiberglass square tubes, exploring their benefits, applications, and why they are the go-to choice for modern engineering.

Why Choose Fiberglass Square Tubes?

Fiberglass square tubes are made from reinforced plastic composites, combining glass fibers with a polymer resin matrix. This unique composition results in a material that is exceptionally strong yet lightweight. Here are the key reasons why industries are switching to fiberglass square tubes:

- Corrosion Resistance: Unlike metal, fiberglass does not rust or corrode, making it ideal for harsh environments like marine or chemical plants.

- Lightweight: Fiberglass tubes weigh significantly less than steel or aluminum, reducing transportation and installation costs.

- High Strength-to-Weight Ratio: Despite their light weight, fiberglass tubes offer impressive structural integrity.

- Customization: Custom fiberglass square tubes can be tailored in size, shape, thickness, and finish to meet specific project requirements.

- Non-Conductive: Fiberglass is an excellent insulator, making it safe for electrical applications.

Applications of Custom Fiberglass Square Tubes

The versatility of custom fiberglass square tubes makes them suitable for a wide range of industries. Below are some of the most common applications:

1. Construction and Infrastructure

In construction, fiberglass square tubes are used for structural supports, railings, and frameworks. Their corrosion resistance makes them ideal for bridges, walkways, and buildings exposed to moisture or chemicals. Custom sizes ensure seamless integration into complex designs.

2. Marine and Offshore Projects

The marine industry relies on fiberglass square tubes for docks, boat components, and offshore platforms. Their ability to withstand saltwater corrosion ensures long-lasting performance in harsh marine environments.

3. Industrial Manufacturing

Factories and chemical plants use fiberglass tubes for piping systems, supports, and equipment frameworks. The non-conductive nature of fiberglass enhances safety in environments with electrical hazards.

4. Renewable Energy

In wind and solar energy projects, fiberglass square tubes are used in turbine blades, mounting structures, and panel supports. Their lightweight nature reduces the load on installations, while their durability ensures longevity.

5. Recreational and Outdoor Structures

From playground equipment to outdoor furniture, fiberglass square tubes offer a durable, weather-resistant solution for recreational applications. Custom colors and finishes enhance aesthetic appeal.

| Industry | Application | Key Benefit |

|---|---|---|

| Construction | Structural supports, railings | Corrosion resistance |

| Marine | Docks, boat components | Saltwater durability |

| Industrial | Piping, equipment frameworks | Non-conductive safety |

| Renewable Energy | Turbine blades, mounts | Lightweight strength |

| Recreational | Playgrounds, furniture | Weather resistance |

Advantages of Custom Fiberglass Square Tubes

Customization is a key factor that sets fiberglass square tubes apart from standard materials. Here’s how tailored solutions benefit your projects:

1. Tailored Dimensions

Custom fiberglass square tubes can be manufactured to precise dimensions, ensuring a perfect fit for your project. Whether you need thin-walled tubes for lightweight applications or thick-walled tubes for heavy-duty structures, customization delivers.

2. Color and Finish Options

Fiberglass tubes can be produced in various colors and finishes, from matte to glossy, to match aesthetic or branding requirements. UV-resistant coatings can also be applied for outdoor durability.

3. Enhanced Material Properties

Manufacturers can adjust the resin and fiber composition to enhance specific properties, such as fire resistance, chemical resistance, or thermal insulation, based on project needs.

4. Cost-Effective Production

Custom fiberglass tubes are produced using pultrusion or molding processes, which are cost-effective for both small and large batches. This ensures affordability without compromising quality.

Image: Custom fiberglass square tubes in vibrant colors for aesthetic applications.

How Are Custom Fiberglass Square Tubes Made?

The manufacturing process for custom fiberglass square tubes typically involves pultrusion, a continuous process that ensures consistency and precision. Here’s a step-by-step overview:

- Material Selection: High-quality glass fibers and resins (e.g., polyester, epoxy) are chosen based on the desired properties.

- Pultrusion Process: Fibers are pulled through a resin bath and then through a heated die, forming the square tube shape.

- Curing: The tube is cured to harden the resin, ensuring structural integrity.

- Cutting and Finishing: Tubes are cut to specified lengths and finished with coatings or textures as needed.

- Quality Control: Each tube undergoes rigorous testing for strength, dimensional accuracy, and surface quality.

This process allows manufacturers to produce tubes with consistent quality and tailored specifications, meeting the demands of diverse industries.

Comparing Fiberglass Square Tubes to Other Materials

To understand the value of fiberglass square tubes, it’s helpful to compare them to alternatives like steel, aluminum, and PVC. The following table highlights key differences:

| Material | Weight | Corrosion Resistance | Cost | Customization |

|---|---|---|---|---|

| Fiberglass | Lightweight | Excellent | Moderate | High |

| Steel | Heavy | Poor (requires coating) | High | Moderate |

| Aluminum | Moderate | Good | High | Moderate |

| PVC | Lightweight | Excellent | Low | Low |

Fiberglass stands out for its balance of lightweight design, corrosion resistance, and customization options, making it a superior choice for many applications.

How to Choose the Right Custom Fiberglass Square Tubes

Selecting the right fiberglass square tubes for your project requires careful consideration of several factors:

- Project Requirements: Determine the load-bearing capacity, environmental conditions, and aesthetic needs.

- Dimensions: Specify the exact size and wall thickness to ensure compatibility with your design.

- Material Properties: Choose resins and fibers that match your needs, such as UV resistance for outdoor use.

- Manufacturer Expertise: Work with a reputable supplier with experience in custom fiberglass solutions.

- Budget: Balance customization costs with long-term savings from durability and low maintenance.

Where to Buy Custom Fiberglass Square Tubes in 2025

Finding a reliable supplier is crucial for obtaining high-quality custom fiberglass square tubes. Look for manufacturers with a proven track record, advanced production capabilities, and excellent customer support. Many suppliers offer online catalogs and consultation services to help you specify your requirements. Be sure to request samples or technical data sheets to verify material quality before placing a large order.

Conclusion

Custom fiberglass square tubes offer a versatile, durable, and cost-effective solution for a wide range of industries. Their lightweight design, corrosion resistance, and customization options make them an ideal choice for construction, marine, industrial, and renewable energy projects. By partnering with a trusted manufacturer, you can create tailored solutions that meet your exact specifications, ensuring long-lasting performance and value. As industries continue to innovate, fiberglass square tubes will remain at the forefront of modern engineering, delivering strength and flexibility for the challenges of tomorrow.

Ready to explore custom fiberglass square tubes for your next project? Contact a reputable supplier today to discuss your needs and discover the possibilities!

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data