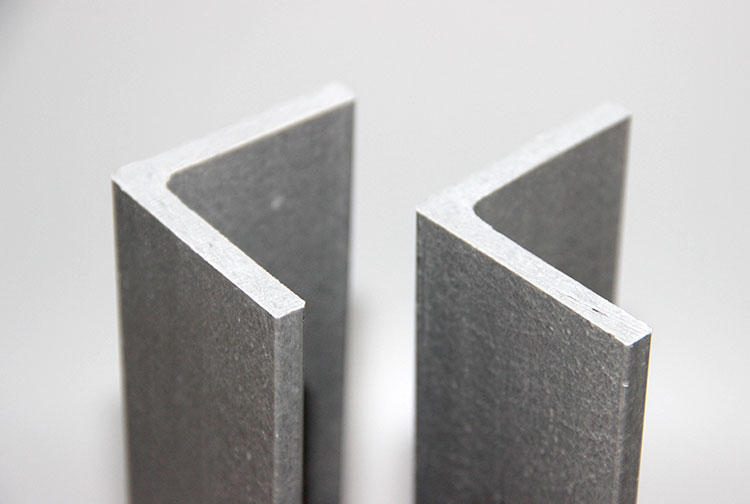

As infrastructure owners and OEMs pursue lighter, stronger, and more durable solutions, composite angles—typically pultruded FRP/GRP L-profiles—are replacing traditional steel and aluminum in corrosive, electrically sensitive, and weight-critical environments. Choosing the right composite angle suppliers ensures consistent quality, on-time delivery, and engineering support across global projects.

Why Composite Angles Are in High Demand

- Corrosion resistance: No rust in marine, chemical, or coastal settings.

- Lightweight & high specific strength: Easier handling, lower transport and installation costs.

- Electrical & thermal insulation: Non-conductive and RF transparent for substations and telecom.

- Low maintenance: Longer service intervals and better lifecycle economics.

- Design flexibility: Pultruded and fabricated to tight tolerances and custom dimensions.

Composite Angles vs. Steel Angles

| Feature | Composite Angles (FRP/GRP) | Steel Angles |

|---|---|---|

| Corrosion Resistance | Excellent (no rust) | Prone to rust in harsh environments |

| Weight | Lightweight, easy to install | Heavy, higher lifting costs |

| Electrical Conductivity | Non-conductive | Conductive |

| Maintenance | Low (no painting required) | Regular anti-corrosion painting |

| Service Life | Long in corrosive settings | Shorter in corrosive settings |

What Reliable Composite Angle Suppliers Provide

- Engineering & customization: L-angles from 25×25×3 mm to 150×150×12 mm (or custom), tailored resin systems (isophthalic, vinyl ester, epoxy).

- Standards & compliance: ISO quality systems and test data aligned to common ASTM/EN specs.

- Fabrication services: Drilling, notching, cutting, surface finish, and assembly kits.

- Global logistics: Export packing, palletization, and multi-modal shipping.

- Cost efficiency: Competitive pricing for volume projects without compromising quality.

Typical Applications

- Electrical substations, cable ladders, and non-conductive framing

- Marine & offshore platforms, walkways, and handrails

- Chemical plants and cooling towers

- Architectural trims, façades, and rooftop structures

- Telecom, radar, and RF-transparent framing

FAQ: Composite Angle Suppliers

What sizes of FRP/GRP composite angles are available?

Common legs range from 25–150 mm with thickness 3–12 mm. Custom leg lengths, thickness, and colors are available upon request.

How do I choose resin systems?

For general purpose, isophthalic polyester; for aggressive chemicals or high temperature, vinyl ester; for high performance bonding or structural needs, epoxy.

Can suppliers provide machining and kits?

Yes. Reputable composite angle suppliers offer precision cutting, drilling, surface finishing, and kit packaging for faster on-site assembly.

What documentation should I expect?

Material datasheets, QA certificates, dimensional drawings, and test reports aligned with ISO/ASTM/EN requirements.

Work With a Trusted Composite Angle Manufacturer

Need quotes or technical support for composite angle suppliers? We provide FRP/GRP angle profiles with custom dimensions, fast lead times, and global shipping.

- Custom sizes & fabrication

- ISO-managed production, ASTM/EN test data

- Global logistics and export packing

Visit our website: www.frpzs.com

WhatsApp: +86 15303735673

Email: Jessica@frpzs.com

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data