Since 2005 / One stop supplier

The coiling machine functions as a sophisticated take-up unit. As the cured FRP rebar exits the final cutting saw or cooling section of the pultrusion line, it is fed directly to the coiler.

Applicable:

Gfrp Rebar

| Feature | Benefit |

| Precision Tension Control | Employs advanced servo or frequency control systems to maintain consistent winding tension, preventing rebar deformation or slippage, thus ensuring product integrity. |

| Traversing Winding System | Features a precise traverse mechanism that layers the rebar neatly and evenly across the spool, maximizing coil capacity and creating stable, uniform packages. |

| High-Speed Synchronization | Automatically synchronizes its speed with the main pultrusion line's haul-off unit, ensuring seamless, non-stop operation and eliminating production bottlenecks. |

| Adjustable Coiling Diameter | Offers the flexibility to adjust the inner and outer coil diameters, accommodating various customer or logistical requirements. |

| Durable & Robust Build | Constructed with heavy-duty steel and high-precision components to withstand continuous industrial operation and the high pulling forces of the rebar line. |

| Automatic Cut and Eject (Optional) | Can be configured with an automatic cutting mechanism and coil ejection system, significantly reducing manual labor and improving cycle time. |

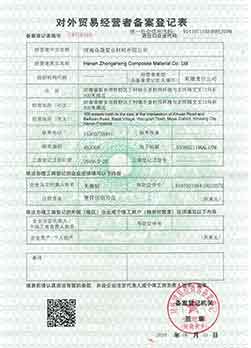

We are both manufacturer trading and company. We have our own factory and we have better service ofoverseas customers. Welcome to send your inquiry!

We can supply a few pieces FREE samples if we have some in stock, and you only need to pay the freight cost by yourself. Welcome to send your inquiry for FREE samples!

10-15days after receiving the deposit based on the MOQ. Normally, 30-35days to finish the order for a 20ft container. Welcome to ask for the detailed delivery time according to your order quantity!

Our whole production lines and products have been certificated by IS09001:2015, and it's been followed strictly. We also have the professional QC team, and each our package worker will be in charge of the final inspection according to the QC instruction before packing.

Basically, the payment terms areT/T,L/C at sight. Western Union, Paypal, Moneygram, Alipay Credit card are acceptableforsample order.

We accept all OEM orders,just contact us and give me your design,we will offer you a reasonable price ASAP.

The quality of the product is very good, all performance tests have passed, and the service attitude of the docking staff is very good

ClydeEngineer, From india

Compared with our local products, the quality of this batch of profiles is quite good, it is worth recommending

DevinCEO, From Germany

The engineer has comprehensive professional knowledge, answered many questions, and put forward many useful suggestions, which made the plan more perfect

AaronCTO, From Mexico

Quote

Email: Jessica@frpzs.com

Phone

Phone+86-15303735673

WhatsApp

+86 15303735673

WeChat

+86-15303735673