Fiber Reinforced Polymer (FRP) composite profiles are fast becoming a cornerstone of modern construction. Comprised of high-strength fibers—such asfiberglass, carbon, or basalt—embedded in polymer matrices like polyester, vinyl ester, or epoxy, FRP composite profiles are revolutionizing industries with their unique balance of strength, weight, durability, and versatility. But what exactly ARE FRP composite profiles, and why are they so popular in today’s construction landscape? In this in-depth article, we'll explore their definition, manufacturing process, performance benefits, key applications, and considerations—delving into how they stack up against traditional building materials, and what the future holds for these innovative profiles.

1. What Are FRP Composite Profiles?

FRP composite profiles—also known as fiber-reinforced polymer profiles—combine the tensile strength of fibers with the flexibility and corrosion-resistant properties of polymer resins. The result is a structural element that is lighter than metal options but delivers comparable load-bearing capacity.

1.1. Core Components

- Reinforcement fibers: These often include fiberglass (E‑glass, S‑glass), carbon fiber, or basalt fiber—each contributing specific mechanical properties.

- Polymer matrix: Polyester, vinyl ester, and epoxy resins are typical choices; they bind the fibers and transfer loads across the material.

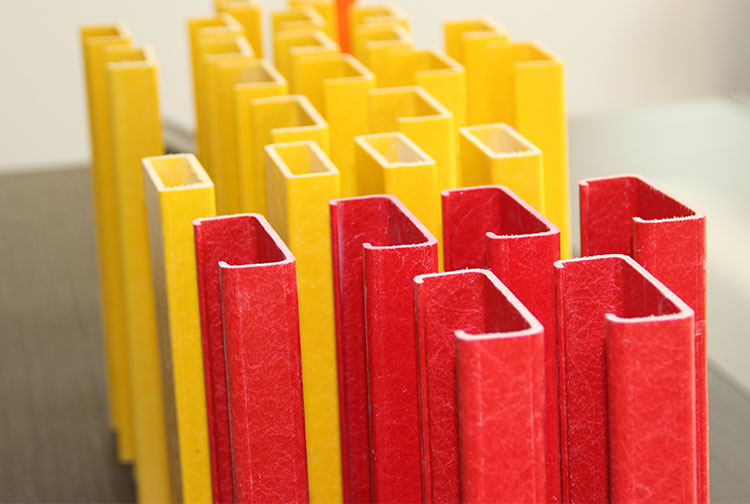

- Profile geometry: FRP profiles come in I-beams, channels, angles, tubes, rods, grating, and custom extruded shapes—offering unmatched design flexibility.

1.2. Manufacturing Processes

FRP composite profiles are produced through several advanced methods:

| Process | Description | Advantages | Common Uses |

|---|---|---|---|

| Pultrusion | Continuous pulling of fibers through a heated resin bath and shaped die. | Precision, uniform cross-sections, high production speed. | I-beams, channels, rods, angles. |

| Resin Transfer Molding (RTM) | Fibers placed in closed mold; resin injected under pressure. | Complex shapes, high-quality surface finish. | Panels, custom profiles, architectural sections. |

| Filament Winding | Continuous fiber resin winding around a rotating mandrel. | Excellent for cylindrical or tubular parts. | Pipes, tanks, pressure vessels. |

2. Key Advantages of FRP Composite Profiles

The rise in popularity of FRP composite profiles stems from a synergy of benefits:

- Lightweight yet strong: Compared to steel, FRP profiles offer comparable flexural and tensile strength at roughly half the weight—ideal for applications where weight saving matters.

- Exceptional corrosion resistance: Bulwark against chemicals, moisture, salt spray, and UV—making them ideal in marine, wastewater, and chemical plant environments.

- Electrically non-conductive: Ideal for power substations, telecom infrastructure, and electrified transit systems.

- Low maintenance: With minimal need for painting, lubrication, or coating, lifecycle costs are significantly lower.

- Design flexibility: Custom cross-sections, integrated functionalities (e.g., cable routing), and aesthetic finishes are easily achieved.

- Thermal insulation: Low thermal conductivity limits heat transfer—beneficial for building envelopes and chill systems.

- Long service life: When specified correctly, structures can exceed 30–50 years before significant degradation.

3. FRP Composite Profiles vs Traditional Materials

| Property | FRP Composite | Steel | Aluminum |

|---|---|---|---|

| Density (g/cm³) | 1.5–1.9 | 7.85 | 2.7 |

| Tensile Strength (MPa) | 300–900 (fiber-dependent) | 250–650 | 200–550 |

| Corrosion Resistance | Excellent (non-corrosive) | Poor (requires coating) | Good to excellent |

| Thermal Conductivity (W/m·K) | 0.3–0.4 | 50–60 | 150–200 |

| Electrical Conductivity | Non‑conductive | Conductive | Conductive |

| Maintenance Needs | Low | High | Moderate |

| Initial Cost | Medium–High | Medium | High |

4. Why Are FRP Composite Profiles Gaining Popularity in Construction?

Here are the main drivers behind their rapid adoption:

4.1. Structural Efficiency in Bridges and Walkways

FRP grating, handrails, beams, and decking are used in pedestrian bridges, boardwalks, and modular overpasses. Reduced self-weight leads to smaller substructures, easier handling, and faster installation.

4.2. Corrosion-Free Structural Elements in Harsh Environments

Coastal, wastewater, and chemical processing structures benefit from FRP’s chemistry resistance—eliminating the need for frequent repainting or corrosion repairs.

4.3. Electrically Insulating Components in Power Infrastructure

FRP bolsters safety and reliability in substations by avoiding conductive pathways—especially crucial near high-voltage busbar supports and lightning protection zones.

4.4. Fire-Resistant and Lightweight in Buildings

Fire-adapted resins and FRP sandwich panels contribute to lightweight roof systems, façade solutions, and staircases with regulatory approval for flame spread and smoke performance.

4.5. Sustainable and Low Life-Cycle Cost Solutions

Despite higher initial costs, FRP offers significant savings in operating life—less maintenance, long service life, and recyclable thermoset components. LEED and BREEAM certifications benefit from reduced embodied energy.

5. Applications Snapshot

- Railings & Handrails: Safe, slip-resistant, corrosion-resistant balustrades along decks, marine piers, and public walkways.

- Structural I-beams and Angles: Supporting platforms, catwalks, equipment mounts in wastewater plants, power stations, and food processing facilities.

- Grating & Flooring Panels: Ventilated, non-slip floors for pumping stations, chemical plants, and offshore rigs.

- Pipes & Tanks: Filament-wound FRP pipes and storage vessels for corrosive liquids, potable water, sewage, and petroleum products.

- Architectural Features: Profiles for canopies, façades, sunshades, and mullions—designed for color, finish, and integration with structural systems.

6. Durability and Environmental Performance

6.1. UV Resistance

Resins with UV inhibitors preserve appearance and prevent fiber degradation—avoiding chalking, discoloration, and strength loss.

6.2. Thermal Cycling & Freeze-Thaw

With low water absorption (<0.2%) and minimal coefficient of thermal expansion, FRP profiles resist cracking and delamination—even at –40 °C to +80 °C climates.

6.3. Chemical Resistance

By choosing the right resin (e.g., vinyl ester for acids or epoxy for alkalis), FRP withstands aggressive pH ranges, salts, solvents, and microbial exposure in water treatment facilities.

6.4. Fire Safety

While polymer resins are combustible, FRP profiles can be engineered to meet Class A/B fire ratings using special resin systems and additives—allowing use in building codes with flame spread limits.

7. Design Considerations & Limitations

- Thermal expansion: FRP has ~10× higher expansion than steel, so designers must account for temperature-dependent expansion joints.

- Creep & relaxation: Under sustained loads, slight deformation may occur—important in long-span applications.

- Fire and smoke considerations: Even rated FRP can release smoke and toxic gases—ventilation and protection strategies must be in place.

- UV aging: Exposed resin surfaces need coatings or inhibitors in long-term sunlight exposure.

- Initial cost: Typically 20–50% cost premium over steel or aluminum, but life-cycle savings often justify the investment.

- Standard compliance: Select profiles certified by relevant standards—AISC for load-bearing, ASTM for grating, FM/UL for fire ratings.

8. Future Trends in FRP Composite Profiles

8.1. Hybrid Fiber Systems

Combining carbon and glass fibers in optimized ratios yields lighter, stiffer, and more cost-effective profiles for high-performance sectors like aerospace and sports infrastructure.

8.2. Thermoplastic Matrix Growth

Next-gen thermoplastic profiles—like PEEK and PPS—offer recyclability and secondary forming options with minimal waste.

8.3. Embedded Smart Technologies

Embedding strain gauges, sensors, or heating elements into extruded profiles enables structural health monitoring and de-icing in real-time.

8.4. Additive Manufacturing & Customization

Combining 3D printed inserts with pultruded skins allows optimized, load-specific profiles—opening the door to mass customization.

8.5. Sustainability Emphasis

Wider use of recycled fibers and bio-based resins will further reduce carbon footprints—propelling FRP into greener building certifications.

Conclusion

FRP composite profiles offer an unmatched package of lightweight, corrosion resistance, electrical insulation, design flexibility, and longevity. Their growing adoption in construction—from handrails and walkways to infrastructure components and façades—signals a shift toward smarter, resilient building solutions.

By understanding the material properties, fabrication methods, advantages, and limiting factors of FRP profiles, architects, engineers, and builders can confidently integrate them into future-ready designs—maximizing performance, sustainability, and lifecycle value.

If you’re ready to explore FRP for your next project, speak with a materials specialist or manufacturer to identify the right resin-fiber-resin system tailored to your engineering needs.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data