Fiber Reinforced Plastic Price

Introduction:

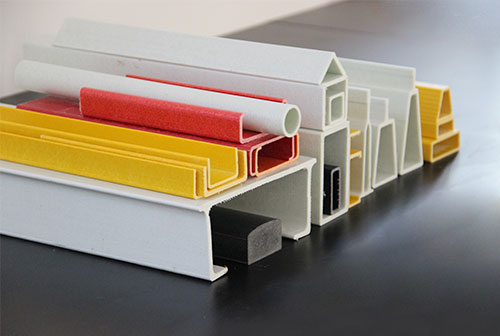

Fiber reinforced plastic (FRP), also known as fiberglass reinforced plastic, has emerged as a revolutionary material in diverse industries due to its exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. However, understanding the factors that determine FRP price is crucial for making informed purchasing decisions and optimizing project costs. In this comprehensive guide, we'll unravel the intricacies of FRP pricing and explore the key determinants that influence its cost.

Factors Affecting FRP Price:

The price of FRP is not a fixed value but rather a dynamic variable influenced by a multitude of factors. These factors can be broadly categorized into three main groups:

1. Material Factors:

Fiber Type: The type of fiber used in the FRP composite significantly impacts its price. Carbon fiber, being the strongest and lightest option, commands the highest price, followed by glass fiber and aramid fiber.

Resin Type: The resin matrix, which binds the fibers together, also plays a role in FRP pricing. Epoxy resins are generally more expensive than polyester resins due to their superior performance properties.

Fiber Content: The proportion of fibers within the FRP composite directly influences its cost. Higher fiber content generally leads to a higher price as it enhances the material's strength and stiffness.

2. Manufacturing Factors:

Production Method: The manufacturing process employed to produce FRP components can affect their cost. Continuous pultrusion, a common method, is relatively cost-effective, while more complex techniques like hand layup or compression molding may incur higher expenses.

Part Complexity: The complexity of the FRP component's design and geometry significantly impacts its price. Intricate shapes, tight tolerances, and specialized tooling requirements can drive up manufacturing costs.

Production Volume: The volume of FRP components ordered can influence the unit price. Higher order quantities often lead to economies of scale, resulting in lower per-unit costs.

3. Market Factors:

Supply and Demand Dynamics: The availability of raw materials, such as fibers and resins, and the overall demand for FRP products can influence pricing. Fluctuations in supply and demand can lead to price variations.

Regional Factors: The location of the FRP manufacturer and the target market can also impact pricing. Labor costs, transportation expenses, and local regulations can contribute to price differences.

Competitive Landscape: The competitive landscape within the FRP industry can influence pricing strategies. Manufacturers may adjust prices based on competitor offerings and market trends.

FRP Cost Breakdown:

The overall cost of FRP components can be broken down into several key elements:

Raw Material Costs: The cost of fibers, resins, and additives accounts for a significant portion of the total FRP price.

Manufacturing Costs: The expenses associated with the production process, including labor, energy, and tooling, contribute to the overall cost.

Overhead Costs: Additional costs such as research and development, quality control, and marketing also factor into the final price.

Profit Margin: Manufacturers incorporate a profit margin into the FRP price to ensure business sustainability and growth.

FRP Pricing Strategies:

FRP manufacturers employ various pricing strategies to optimize their profitability and attract customers. Common strategies include:

Cost-Plus Pricing: This method involves adding a predetermined profit margin to the total cost of production to determine the selling price.

Value-Based Pricing: This strategy focuses on the value the FRP product delivers to the customer, considering factors such as performance, durability, and cost savings.

Competitive Pricing: Manufacturers may set prices based on the offerings of their competitors, aiming to match or undercut competitor prices while maintaining profitability.

Market Segmentation: FRP prices may vary depending on the target market, considering customer preferences, industry standards, and competitive dynamics.

Conclusion:

The price of fiber reinforced plastic (FRP) is influenced by a complex interplay of material, manufacturing, and market factors. Understanding these determinants is crucial for making informed purchasing decisions and optimizing project costs. By carefully evaluating the factors that contribute to FRP pricing, you can effectively negotiate with suppliers and procure high-quality FRP components at the best possible price.

Remember, FRP pricing is not a static concept but rather a dynamic process that responds to market conditions, technological advancements, and customer demands. Stay informed about the latest trends and developments in the FRP industry to make strategic procurement decisions that align with your business objectives and budget constraints.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data