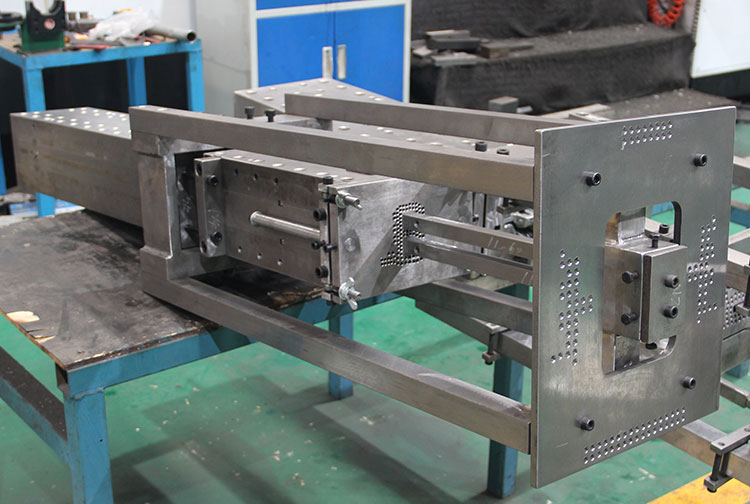

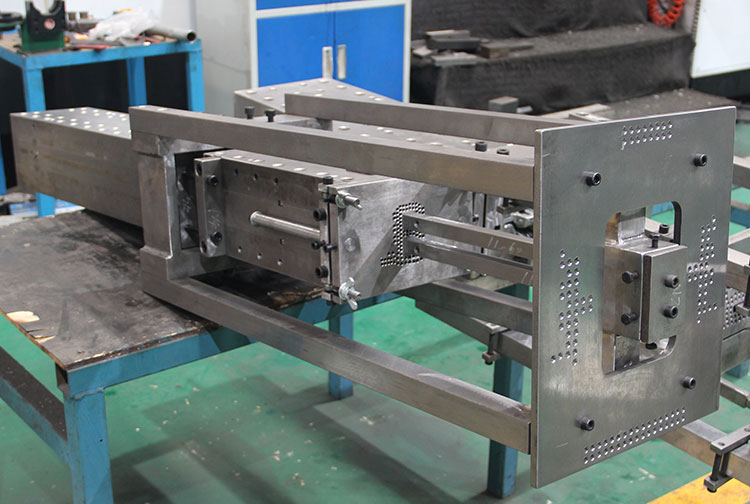

Composite Pultrusion Mold

The production of fiberglass reinforced plastic (FRP) profiles through the pultrusion process relies on advanced molds, known as pultrusion dies or pultrusion molds. These molds are essential for shaping continuous composite pultrusion profiles used in construction, aerospace, and other industries. This news article delves into the role of FRP pultrusion dies, focusing on their design, manufacturing, and maintenance.

Understanding Pultrusion Dies

A

pultrusion die is a precision tool that shapes fiber-reinforced composites during the pultrusion process. Unlike traditional molding, pultrusion pulls glass fibers and

thermoset resins through a

heated die to form profiles with consistent cross-sections. The

mold cavity within the

profile die determines the shape of the final product, such as rods or beams. The

continuous forming die ensures a seamless production process, making pultrusion ideal for high-volume manufacturing.

Materials and Manufacturing

Most

pultrusion molds are crafted from durable

steel dies to withstand the abrasive nature of glass fibers and high curing temperatures. The

die manufacturing process uses precision machining to create a smooth

mold cavity, ensuring consistent resin flow. Some systems incorporate a

resin injection mold to evenly distribute

thermoset resins, enhancing the structural integrity of the

composite pultrusion mold output. Advanced coatings are often applied to

precision dies to reduce wear.

Optimizing Die Design

Effective

die design is crucial for producing high-quality FRP profiles. The

mold cavity must be engineered to account for resin shrinkage and fiber alignment. The

heated die maintains precise temperature control to ensure proper curing, while complex

thermoset molds may feature multiple heating zones. A well-designed

profile die guarantees dimensional accuracy and a smooth surface finish.

Maintenance for Longevity

Die maintenance is vital to sustain production quality. The abrasive action of fibers can wear down the

mold cavity, affecting precision. Regular cleaning and inspection of the

steel die prevent defects, while maintenance of the

resin injection mold ensures consistent resin flow. A robust

die maintenance schedule minimizes downtime and extends the lifespan of the

continuous forming die.

Conclusion

The

pultrusion die is at the heart of

FRP pultrusion production, enabling the creation of strong, lightweight profiles. Innovations in

die design,

die manufacturing, and

precision dies continue to drive efficiency and quality. By prioritizing

die maintenance, manufacturers can ensure reliable performance of

composite pultrusion molds, meeting the growing demand for FRP profiles across industries.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data