How to Start a GFRP Rebar Manufacturing Business — A Deep Industry Exploration

Author | Industry Analyst – Special Report

Introduction: In environments exposed to seawater, de-icing salts, or chemicals, traditional steel reinforcement often suffers from corrosion, resulting in costly maintenance and safety concerns. In recent years, Glass Fiber Reinforced Polymer (GFRP) rebar has emerged as a reliable alternative thanks to its corrosion resistance, lightweight nature, and long service life. This article explores, in depth, how to transform the idea of “manufacturing GFRP rebar” into a sustainable and profitable business, from market research and production technology to financing, equipment, and risk management.

1. Market Outlook: Why Now?

Growth Trend: The global GFRP/FRP rebar market has expanded rapidly in recent years. Industry forecasts estimate a compound annual growth rate (CAGR) between 5% and 12% through 2025–2030. The Asia-Pacific region (especially China and India) and North America are leading the demand surge, driven by infrastructure, marine, and underground projects.

Key Drivers: Coastal bridges, seawalls, wastewater treatment facilities, and chemical plants require corrosion-resistant materials. The rising focus on life cycle cost (LCC) reduction has accelerated GFRP adoption.

Takeaway: The industry is shifting from pilot production to large-scale application. With certified quality, engineering acceptance, and stable distribution, this is still a favorable time to enter the market.

2. Technology and Manufacturing Process (Pultrusion Core)

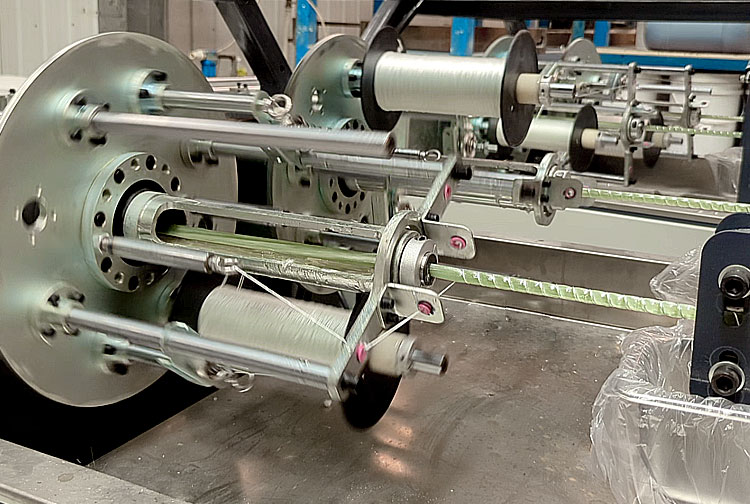

Main Process – Pultrusion: GFRP rebars are primarily made through pultrusion: continuous glass fibers are impregnated with resin and pulled through a heated die to form solid, ribbed rods. The process supports continuous, high-volume production and allows control over mechanical and bonding properties.

Technical Highlights:

- Fiber Configuration: The mix of unidirectional roving and mats determines tensile and transverse strength.

- Resin System: Unsaturated polyester, phenolic, or epoxy systems are common; each has different cost, durability, and processing characteristics.

- Surface Treatment: Proper ribbing or sand coating ensures adhesion to concrete — a key factor in meeting design codes and gaining engineering acceptance.

3. Factory Setup, Equipment, and Raw Materials

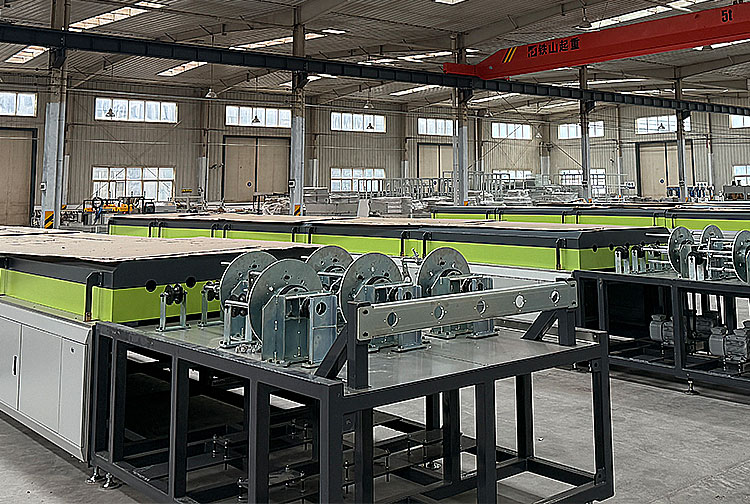

Plant Size: A small pilot facility may require a few hundred square meters; a medium-scale factory capable of serving construction projects generally needs 1,000–5,000 m², including production, storage, and quality control areas.

Core Equipment:

- Pultrusion line (puller, heated die, cutter)

- Resin mixing & heating system

- Fiber creel and alignment units

- Surface treatment or sand-coating line

- Testing equipment (tensile, flexural, bond tests, salt spray chamber)

Investment Range: A single basic pultrusion line can cost tens of thousands to hundreds of thousands of USD depending on automation and output. For a full setup including lab and utilities, total startup investment typically ranges from $100,000 to $2,000,000, depending on capacity and location.

4. Quality, Testing, and Standards

Design Codes and References: The ACI 440 series (e.g., ACI 440.1R, ACI 440.3R) are widely referenced for FRP rebar structural design. Products must pass tensile strength, modulus, bond, chemical resistance, and durability tests to be accepted in construction projects.

Quality Control:

- Raw material inspection (fibers, resin, fillers)

- Process monitoring (temperature, pull speed, resin content)

- Product sampling and testing

- Batch traceability and certification documentation

Engineering Collaboration: Partnering with structural designers and engineering institutes is essential to ensure your rebar meets local acceptance standards and to assist with design substitutions where GFRP replaces steel.

5. Business Model and Client Development

Target Clients:

- Infrastructure owners (bridges, ports, tunnels)

- Utility and wastewater projects

- Precast concrete manufacturers

Sales Channels: Direct sales to contractors and precasters; technical partnerships with design institutes; regional distributors.

Pricing Strategy: GFRP rebar costs more than steel per unit weight but provides a lower life-cycle cost in corrosive environments. Focus on value pricing—emphasizing corrosion resistance, reduced maintenance, and longer service life.

6. Cost Structure, Financing, and Profitability

Major Costs: Equipment depreciation, raw materials, labor, energy, quality testing, logistics, and certification.

Profit Factors: Line utilization rate, product quality, order stability, and operational efficiency.

Financing: Combine owner equity with equipment loans, local investment funds, or long-term supply contracts with construction clients. Securing pilot project commitments or advance purchase agreements significantly reduces financing risk.

7. Risks and Sustainability

Technical Risk: Insufficient bonding or quality variation may lead to rejection or legal disputes — invest early in R&D and testing, and provide training for onsite installation.

Regulatory Risk: Building codes and standards vary by region; early engagement with local authorities helps secure pilot approvals.

Supply Chain Risk: Resin or fiber price fluctuations — establish dual sourcing and safety stock strategies.

Environmental Impact: Although GFRP is not recyclable like steel today, its long service life reduces total environmental footprint. Developing recyclable resin systems is a promising long-term direction.

8. Step-by-Step Action Plan

Preparation (0–3 months)

- Conduct regional market research and collect design code requirements.

- Contact pultrusion equipment suppliers for pilot trials.

- Estimate capital and working capital needs.

Pilot Stage (3–9 months)

- Set up a demo line and testing lab.

- Partner with local engineering firms for pilot projects.

- Begin certification or standard compliance processes.

Expansion (9–24 months)

- Scale production, build distribution channels, and establish engineering case studies.

- Optimize formulas and reduce costs through local sourcing.

9. Learning from Industry Examples

Study case reports from national transportation and construction agencies, technical literature on pultrusion and bond performance, and commercial market reports for capacity planning and benchmarking.

Conclusion: From “Material Replacement” to “Engineering Trust”

The GFRP rebar opportunity lies not only in material performance but also in engineering credibility. To build a sustainable, profitable GFRP rebar business, four pillars must align — technology, standards, market partnerships, and financing. Start small, validate your process with certified testing, and use pilot projects to build industry trust. Those who build the foundation now will lead the transformation as GFRP moves from niche to mainstream.

Learn More or Partner With Us

We specialize in fiberglass pultruded profiles, molds, and manufacturing equipment, and can help you establish a turnkey GFRP rebar production line.

Website: www.frpzs.com

Email: Jessica@frpzs.com

WhatsApp: +86 15303735673

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data