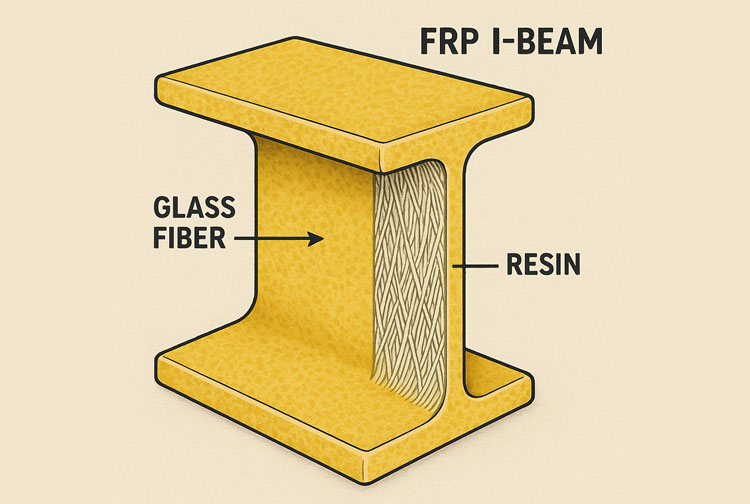

Figure 1: Cross-section of an FRP I-Beam, illustrating the integration of glass fiber within a resin matrix.

Introduction

In the realm of modern engineering and construction, Fiberglass Reinforced Plastic (FRP), also known as Fiber Reinforced Plastics, has emerged as a game-changer. Comprising glass fiber and synthetic resin, FRP combines the strength of traditional materials with unparalleled advantages like corrosion resistance, lightweight and high strength, and non-conductive properties. Among the various FRP profiles, the I-beam stands out due to its structural efficiency and versatility. This article delves into the composition, production, and wide-ranging applications of FRP I-beams, highlighting their role as an eco-friendly material in industries like construction material, chemical equipment, shipbuilding, automotive parts, piping systems, electrical facilities, and even sports equipment.

Composition and Properties of FRP I-Beams

FRP I-beams are a type of composite material made by combining glass fiber as the reinforcement material with a matrix of synthetic resin. The resin can be unsaturated polyester, epoxy resin, or phenolic resin, each chosen based on the specific requirements of the application. These materials work together to create a product with exceptional mechanical strength, making FRP I-beams a viable alternative to traditional steel or aluminum I-beams.

The key properties of FRP I-beams include:

- Lightweight and High Strength: FRP I-beams are significantly lighter than steel, yet they offer comparable or superior strength, reducing structural loads and transportation costs.

- Corrosion Resistance: Unlike metal, FRP does not rust or corrode, making it ideal for harsh environments like chemical plants or marine settings.

- Non-Conductive: This property ensures safety in electrical facilities, where electrical insulation is critical.

- Aging Resistance: FRP I-beams maintain their integrity over time, resisting degradation from UV exposure or extreme temperatures.

- Waterproof and Moisture-Proof: These beams are impervious to water, making them suitable for piping systems and humid environments.

Manufacturing Processes

The production of FRP I-beams relies on advanced composite processes that ensure precision and durability. The primary method is pultrusion, a continuous manufacturing process where glass fibers are pulled through a resin bath and then through a heated die to form a consistent structural profile. This technique is ideal for producing I-beams, H-beams, channel steel, angle steel, square tubes, and round tubes.

Other methods include molding, which is used for more complex or customized profiles, and filament winding, often applied to cylindrical structures like pipes. These processes allow manufacturers to tailor FRP profiles to specific needs, ensuring versatility across applications. The pultrusion process, in particular, is highly efficient, producing industrial profiles with uniform cross-sections and excellent mechanical properties.

| Manufacturing Process | Description | Applications |

|---|---|---|

| Pultrusion | Continuous pulling of glass fibers through resin and a heated die | I-Beams, H-Beams, Channel Steel, Square Tubes |

| Molding | Resin and fibers shaped in a mold under pressure | Customized Profiles, Complex Shapes |

| Filament Winding | Fibers wound around a mandrel and coated with resin | Round Tubes, Piping Systems |

Table 1: Comparison of manufacturing processes for FRP profiles.

Applications of FRP I-Beams

The versatility of FRP I-beams makes them indispensable across multiple industries. Below are some key applications:

Construction Materials

In the construction industry, FRP I-beams serve as construction materials for bridges, walkways, and building frameworks. Their lightweight and high strength properties reduce the overall weight of structures, while their corrosion resistance ensures longevity in outdoor environments. For example, FRP I-beams are used in pedestrian bridges in coastal areas, where saltwater exposure would quickly degrade steel.

Figure 2: FRP I-Beams in a pedestrian bridge, showcasing their lightweight and durable nature.

Chemical Equipment

The corrosion resistance of FRP I-beams makes them ideal for chemical equipment, such as storage tank supports and platforms in chemical processing plants. These beams withstand exposure to acids, alkalis, and other corrosive substances, reducing maintenance costs and enhancing safety.

Shipbuilding

In shipbuilding, FRP I-beams are used for structural components like deck supports and bulkheads. Their waterproof and moisture-proof properties, combined with aging resistance, make them perfect for marine environments, where traditional materials often fail due to rust.

Automotive Parts

The automotive industry leverages FRP I-beams for automotive parts, such as chassis components and load-bearing frames. Their lightweight nature contributes to fuel efficiency, while their mechanical strength ensures durability under stress.

Piping Systems

In piping systems, FRP I-beams are used as supports for pipelines in industries like wastewater treatment and oil and gas. Their waterproof and moisture-proof properties ensure reliability in wet conditions, and their customized profiles allow for tailored solutions.

Electrical Facilities

The non-conductive nature of FRP I-beams makes them a top choice for electrical facilities. They are used in cable trays, insulator supports, and other applications where electrical safety is paramount.

Sports Equipment

In the realm of sports equipment, FRP I-beams are incorporated into lightweight structures like goalposts or fitness equipment frames. Their strength and durability ensure performance under dynamic loads.

Advantages Over Traditional Materials

Compared to traditional materials like steel or aluminum, FRP I-beams offer several advantages. Steel I-beams, while strong, are heavy and prone to corrosion, requiring frequent maintenance in harsh environments. Aluminum is lighter but less durable and more expensive. FRP I-beams, on the other hand, combine the best of both worlds: they are lightweight, strong, and resistant to environmental degradation. Additionally, as an eco-friendly material, FRP reduces the environmental impact of manufacturing and maintenance, aligning with sustainability goals.

Market Trends and Future Prospects

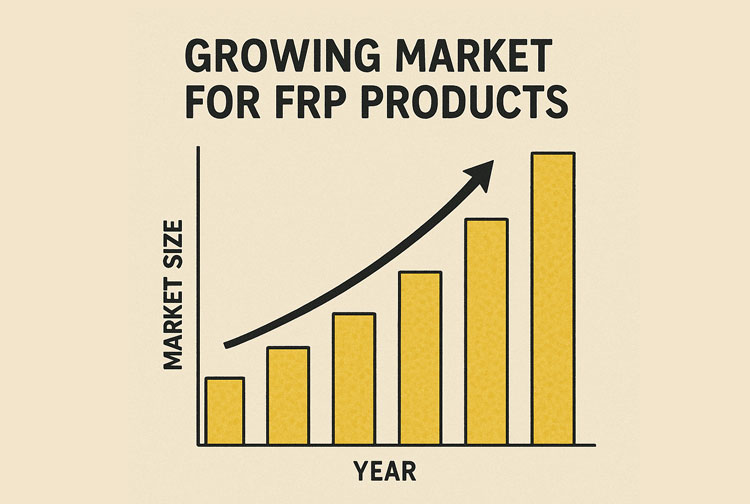

The global market for FRP products is growing rapidly, driven by demand for industrial profiles and structural profiles. Industries are increasingly adopting FRP I-beams for their cost-effectiveness and performance. The ability to produce customized profiles allows manufacturers to meet specific project requirements, from unique dimensions to specialized resin formulations. As industries prioritize sustainability, the eco-friendly material properties of FRP will further boost its adoption.

Figure 3: Market trends for FRP products, highlighting their increasing adoption across industries.

Conclusion

Fiberglass Reinforced Plastic (FRP) I-beams represent a pinnacle of modern engineering, blending glass fiber and synthetic resin to create a composite material with unmatched properties. Their lightweight and high strength, corrosion resistance, non-conductive nature, aging resistance, and waterproof and moisture-proof characteristics make them ideal for applications ranging from construction materials to sports equipment. Manufactured through advanced processes like pultrusion, molding, and filament winding, FRP I-beams offer versatility and reliability. As an eco-friendly material, they are poised to play a significant role in the future of sustainable engineering, driving innovation across industries like chemical equipment, shipbuilding, automotive parts, piping systems, and electrical facilities.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data