pultrusion die design

Henan Zhongsheng is a leading manufacturer of pultrusion dies. We have over 20 years of experience in the design and manufacture of pultrusion dies, and we have a team of experienced engineers who are experts in the field.

In this guide, we will discuss the key factors to consider when designing a pultrusion die. We will also provide a step-by-step guide to the pultrusion die design process.

Key Factors to Consider

When designing a pultrusion die, there are a number of key factors to consider. These include:

The type of FRP product to be produced: The type of FRP product to be produced will determine the shape and size of the die. For example, a die for a pultruded beam will be different from a die for a pultruded panel.

The fiber type and orientation: The type and orientation of the fibers will affect the strength and stiffness of the FRP product. For example, a die for a pultruded product with unidirectional fibers will be different from a die for a pultruded product with bidirectional fibers.

The resin type and cure cycle: The resin type and cure cycle will affect the properties of the FRP product. For example, a die for a pultruded product with a fast-curing resin will be different from a die for a pultruded product with a slow-curing resin.

Step-by-Step Guide to Pultrusion Die Design

The pultrusion die design process can be broken down into the following steps:

Define the product requirements: The first step is to define the requirements for the FRP product. This includes the shape, size, strength, stiffness, and other properties of the product.

Select the fiber type and orientation: The next step is to select the fiber type and orientation. This will affect the strength and stiffness of the product.

Select the resin type and cure cycle: The third step is to select the resin type and cure cycle. This will affect the properties of the product.

Design the die shape and size: The fourth step is to design the die shape and size. This will determine the cross-section of the FRP product.

Select the die materials: The fifth step is to select the die materials. The die materials must be able to withstand the high temperatures and pressures of the pultrusion process.

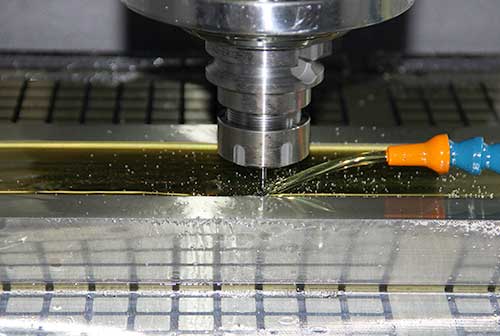

Fabricate the die: The sixth step is to fabricate the die. This can be done by machining or casting.

Henan Zhongsheng's Pultrusion Die Design Process

Henan Zhongsheng follows a rigorous pultrusion die design process that ensures that our dies meet the needs of our customers. Our process includes the following steps:

Consulting with the customer: We consult with the customer to understand their product requirements. This includes the shape, size, strength, stiffness, and other properties of the product.

FEA analysis: We use finite element analysis (FEA) to simulate the flow of resin and fibers through the die. This helps us to identify potential problems and optimize the die design.

Prototype testing: We build a prototype die and test it to ensure that it meets the customer's requirements.

Production: We manufacture the final die to the customer's specifications.

Conclusion

Pultrusion die design is a complex process that requires careful consideration of a number of factors. By following a rigorous design process, manufacturers can ensure that their dies meet the needs of their customers and produce high-quality FRP products.

Henan Zhongsheng is a leading manufacturer of pultrusion dies. We have over 20 years of experience in the design and manufacture of pultrusion dies, and we have a team of experienced engineers who are experts in the field. We are committed to providing our customers with the highest-quality pultrusion dies and services.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data