Henan Zhongsheng is a leading manufacturer of pultruded and molded grating. We have over 20 years of experience in the design and manufacture of these products. We offer a wide range of grating to meet the needs of a variety of applications.

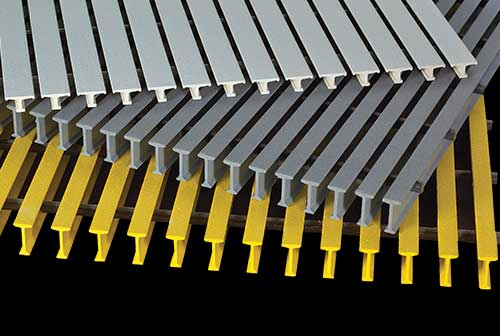

Pultruded Grating

Pultruded grating is a type of grating that is made by pultrusion. Pultrusion is a process that involves pulling a continuous fiber-reinforced resin composite through a heated die. This process results in a strong, lightweight, and corrosion-resistant grating.

Advantages of Pultruded Grating

Strong and durable: Pultruded grating is stronger and more durable than molded grating. This is because the fibers are aligned in the direction of the load, which provides greater strength.

Corrosion-resistant: Pultruded grating is resistant to corrosion, making it ideal for use in harsh environments.

Lightweight: Pultruded grating is significantly lighter than molded grating, making it easier to transport and install.

Customizable: Pultruded grating can be customized to meet specific requirements. For example, the size, shape, and material of the grating can be customized.

Disadvantages of Pultruded Grating

More expensive: Pultruded grating is typically more expensive than molded grating.

Limited design options: Pultruded grating is limited in terms of design options. The shapes and sizes that can be produced are more limited than molded grating.

Molded Grating

Molded grating is a type of grating that is made by molding. Molding is a process that involves pouring a resin into a mold and then curing the resin. This process results in a grating that is strong, durable, and cost-effective.

Advantages of Molded Grating

Cost-effective: Molded grating is typically more cost-effective than pultruded grating.

Wide range of designs: Molded grating is available in a wide range of designs, including different shapes, sizes, and materials.

Easy to install: Molded grating is easier to install than pultruded grating.

Disadvantages of Molded Grating

Not as strong: Molded grating is not as strong as pultruded grating. This is because the fibers are not aligned in the direction of the load.

Not as corrosion-resistant: Molded grating is not as corrosion-resistant as pultruded grating.

More maintenance: Molded grating requires more maintenance than pultruded grating. This is because the resin is more susceptible to damage.

Which Type of Grating is Right for You?

The best type of grating for you will depend on your specific needs and requirements. If you need a strong, durable, and corrosion-resistant grating, then pultruded grating is a good choice. However, if you need a cost-effective grating with a wide range of design options, then molded grating is a better option.

Here are some factors to consider when choosing between pultruded and molded grating:

Strength: If you need a grating that can support heavy loads, then pultruded grating is a better choice.

Corrosion resistance: If you need a grating that can withstand harsh environments, then pultruded grating is a better choice. Cost: If you are on a budget, then molded grating is a better choice.

Design options: If you need a grating with a specific design, then molded grating is a better choice.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data