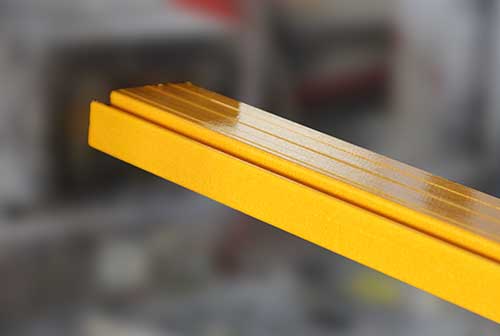

Glass fiber reinforced polymer (GFRP) reinforcement is widely used in the pultrusion process to produce high-strength, lightweight, and corrosion-resistant composites. GFRP reinforcement provides the pultruded profile with its tensile strength and stiffness, while the resin matrix provides the composite with its flexural strength and toughness.

Types of GFRP Reinforcement for Pultrusion

The most common types of GFRP reinforcement used in pultrusion are:

Unidirectional roving: This type of reinforcement is made up of continuous strands of glass fiber that are laid down in a single direction. Unidirectional roving provides the pultruded profile with high tensile strength in the direction of the fibers.

Continuous filament mat: This type of reinforcement is made up of a random mat of glass fibers. Continuous filament mat provides the pultruded profile with strength and stiffness in all directions.

Woven fabric: This type of reinforcement is made up of glass fibers that are woven together to form a fabric. Woven fabric provides the pultruded profile with strength and stiffness in all directions.

Applications of GFRP Reinforcement in Pultrusion

GFRP reinforcement is used in a wide variety of applications in the pultrusion process, including:

Building and construction: GFRP pultruded profiles are used in a variety of building and construction applications, such as beams, columns, and roofing.

Transportation: GFRP pultruded profiles are used in a variety of transportation applications, such as automotive parts, marine components, and railway tracks.

Industrial applications: GFRP pultruded profiles are used in a variety of industrial applications, such as electrical equipment, furniture, and medical devices.

Advantages of Using GFRP Reinforcement in Pultrusion

GFRP reinforcement offers a number of advantages over other types of reinforcement in the pultrusion process, including:

High strength-to-weight ratio: GFRP is a strong and lightweight material, which makes it ideal for applications where weight is a concern.

Corrosion resistance: GFRP is resistant to corrosion, which makes it a good choice for applications where the pultruded profile will be exposed to the elements.

Durability: GFRP is a durable material, which makes it a good choice for applications where the pultruded profile will be subjected to wear and tear.

Conclusion

GFRP reinforcement is a versatile and effective material that can be used to produce a wide variety of pultruded profiles. GFRP offers a number of advantages over other types of reinforcement, including high strength-to-weight ratio, corrosion resistance, and durability.

Additional Information

In addition to the applications mentioned above, GFRP reinforcement is also used in a number of other applications, such as:

Wind turbine blades: GFRP pultruded profiles are used to manufacture the blades of wind turbines.

Offshore oil and gas platforms: GFRP pultruded profiles are used to construct offshore oil and gas platforms.

Bridges: GFRP pultruded profiles are used to reinforce bridges.

GFRP reinforcement is a growing field of technology, and new applications for GFRP pultruded profiles are being developed all the time.

+86 15303735673

+86 15303735673 Jessica@frpzs.com

Jessica@frpzs.com

Technical Data

Technical Data